Diamond Polishing Discs - dry

(See our wet polishing pads here)

Diamond resin polishing discs are a flexible pad for dry polishing all natural stones, concrete and engineered stone.

They are long lasting and fast working.

I carry 125mm (5") and 175mm (7" only)

The Korean range I import will out-perform the cheap discs available online.

Designed to be used dry, they can be used with a tiny amount of water, although this will shorten the life of the pad (a lot of water will destroy them quickly!)

These velcro backed polishing pads simply stick to the velcro backing pad (available seperately, below) that attaches to your polisher.

Maximum speed for my 125mm dry diamond resin polishing pads is 4500 RPM (recommended speed range 2500 - 4500RPM).

Do not use a standard angle grinder (they can be up to 11,000 RPM).

A variable speed angle grinder (usually 3000 to 11000 RPM) used at the lowest speed can be useable.

175mm discs recommended speed range is 2500-3000 RPM. Maximum speed 4000RPM

I can not be responsible for any quality issues if you use high speeds with any of my pads.

You can get reasonable results with an angle grinder using our KGS Swiflex CX ECO pads - see info below.

Tips: It is hard to recommend a grit sequence as this will depend on individual usage and different materials.

Sometimes you may be able to skip grades on some materials, but this is generally not recommended.

Polishing results will vary according to machine and material.

Always work flat, with a little pressure. Too much pressure can shorten the disc's working life.

If applying sealer, follow the manufacturers instructions.

Note - When workers cut, crush, drill, polish, saw or grind products that contain silica, particles are created, which are one-hundredth of the size of a grain of sand. These can get stuck deep in the lungs. Ensure precautions to limit exposure to dust are in place.

Use a half face respirator or a PAPR (Powered air purifying respirator).

See the WA government's info on silica dust here.

It is impossible to make a recommendation on YOUR grinding job. Every job is different.

Essential:

- allow concrete to cure minimum 10 days before polishing

-

do not use single speed angle grinders - too fast

- do not use with water

- order a back pad if you do not have one (see bottom of page)

125mm and 175mm Premium Honeycomb polishing discs

The Premium Honeycomb polishing pads are made in Korea and are a great polishing pad.

Will last considerably longer than other pads (when used at correct speed).

With its ability to deflect heat, it's amazing flexibility, long life and top quality finish, these Honeycomb Diamond Polishing Pads are the best dry polishing pad on the market.

Note - These pads generally leave no discolouring, but occasionally higher grits (#800 and above) may leave slight colour on some lighter coloured surfaces.

- Designed for Flexibility

- Honeycomb pattern

- Great life expectancy

- Exceptional polishing

- Ideal for edging

- Large channels for dust evacuation

- Dry use only

- Made in Korea

Ideal for:

- Concrete

- Hard marble

- Granite

- Natural stone

- Engineered or manufactured stone

- Travertine etc

Specifications:

- Grit: #50, #100, #200, #400, #800, #1500 & #3000

- Diameter: 5"/125mm

- Pattern Type: Diamond Honeycomb Resin

- Suits most 125mm velcro backing pads

All $30 each incl GST

(or one of each at $180 Incl GST)

7"/175mm now in stock:

In #50, #100, #200 and #400 grit

$50 each incl GST

(or one of each at $180 Incl GST)

See them in action here:

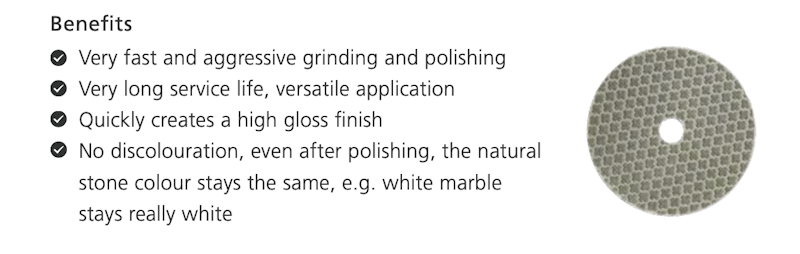

125mm KGS Swiflex XX Discs

These resin discs are designed for use on hand held machinery, and are suitable for edge and surfacing grinding, as well as chamfering.

These pads are for use on natural stones like marble and granite etc, as well as engineered stone, ceramic, concrete and glass.

They can bring out a high gloss finish without discolouring - even white marble will stay white.

They are designed for dry use, but can be used with a little water, although this will shorten the pads life.

- Grit: #60, #120, #200, #400, #800, #1500 & #3000

- Diameter: 5"/125mm

- Suits most 125mm velcro backing pads

- Made by KGS with Swiss Diamond Technology

Suggested usage info:

Marble - Use (#60), #120, #200, #400, #800, #1500, #3000 grits

Granite - Use #60, #120, #200, #400, #800, (#1500) grits

All $30 each incl GST

(or one of each at $180 Incl GST)

See these pads in action below (demonstrated on concrete).

Polishing Discs for use with angle grinder:

125mm Swiflex CX ECO (now in stock)

Swiflex CX ECO diamond sandpaper is available from #60 to #3000 grit.

These can give a reasonable polished result on concrete when used with an angle grinder.

They suit customers who do not have very high requirements for the polishing effect but care about cost.

This means you will get a reasonable result without having to purchase a polisher.

The coarser grits will last up to 2 - 4 times more aggressive than conventional abrasives like sandpaper.

Fine grits will last up to 15 times longer than sand paper.

No discolouration of the surface.

Less dust prolongs life of your grinder, and environmentally safer

Suits marble and concrete

Specifications:

- Can be used up to 11,000RPM, so suits most angle grinders.

- Grits: #60, #120, #200, #400, #800, #1500 & #3000

- Diameter: 5"/125mm

- Dry use only

- With velcro backing

$11 each incl GST

(or one of each at $65 Incl GST)

These photos show some results of using these pads.

Accessories:

Backing pads:

Backing pads with velcro, M14 fitting suits most angle grinders, polishers etc:

4"/100mm from $40 each incl GST

5"/125mm from $45 each incl GST

7"/175mm $75 each incl GST

(Do not spin too fast with too much pressure - glue will overheat and velcro peel off.)

|

| 125mm aluminium (rigid) $65 incl GST ea |

125mm Cushion pads/backing sponge:

Velcro Male and female

Turns a rigid back pad into a slightly more flexible pad when sanding uneven surfaces.

4mm thick, 125mm/5"

$40 each incl GST

Prices correct as of 1/1/26 but subject to change.

Please see my Contact page for Australia wide delivery information.

What is honed concrete?

Honed concrete is like exposed aggregate (where the aggregate, or rock, in the concrete are exposed) but the surface has been ground to a smoother matt finish. It is not as polished as polished concrete (see next).

After laying, the concrete needs to cure for some time - a general rule is the concrete should be cured for 28 days before you start. Once cured, you will need to grind off the top layer of concrete to expose the decorative stone aggregates within the mix.

Use our diamond resin polishing pads to achieve the finish you want.

What is polished concrete?

Polished concrete is a good looking and durable finish that is obtained by polishing a concrete surface with my diamond resin polishing pads until a glossy surface is achieved.

Polished concrete is made by grinding and then polishing your concrete until it reaches the desired look.

Next, a process known as hardening occurs, where the use of a hardener penetrates the concrete, creating a chemical reaction to help harden and dust proof the surface.

During concrete polishing, the surface is processed through a series of steps (in general a minimum of 6 grinding steps are completed for it to be considered polished concrete) utilising progressively finer diamond resin polishing pads.

What is "Grind and seal" concrete?

This is where the concrete substrate is ground back (usually to #200 – #400 grit) and then coated with either a polyurethane or epoxy topical coating to give the look of polished concrete without the labour intensive grinding and polishing.

Decide on the finish you want:

Uniform Finish – The concrete is a uniform colour because there is still a thin layer of cement over the surface.

Light Polish – The thin layer of cement is removed, so a fine sand aggregate is exposed.

Ground Finish – As you polish deeper into the concrete, you begin to expose the larger aggregate (stones) that is in the concrete mix.

Notes on polishing concrete counter tops:

Grinding and polishing results will vary according to the material, machine and operator.

Not all concrete has the strength to produce a high sheen exposed aggregate finish.

Use a machine that operates at 2500 - 4500RPM

If dry polishing, protect yourself from silica dust with a vacuum.

Remove the dust regularly, otherwise it can scratch the surface.

If wet polishing, make sure you are protected from electrocution with a RCD.

The water will remove the dust, so scratching is less likely.

Which grit to use?

The lower the number, the coarser the grit, and the more material it will remove.

#60 grit is the lowest, and most aggressive disc.

The more aggressive, coarser grits work best at exposing aggregates and removing blemishes.

The higher the number, the finer the grit, and less material will be removed, and more polishing will be achieved.

The finer grits are for final polishing. #3000 grit is the finest and least aggressive disk.

Progress to higher grit levels until you achieve the desired surface sheen and smoothness.

Apply sealer as per manufacturers instructions.

You will need to select the grit that removes any uneven surfaces and scratches.

Double the grit size with each stage, gradually breaking down the surface irregularities until the surface is sufficiently smooth. Stop at the grit that offers the polish you want.

Trial and error with a few different pads will help you achieve the finish you need.

If you polish only, you may get a smooth, but matt surface (honed).

To get a high gloss finish, a densifier or polished concrete clear sealer from Crommelin Chemicals, Sika (both available at Bunnings) or Fosroc by Parchem is required.

The densifier will harden the surface, increase abrasion and water resistance and reduce dusting.

The polished concrete clear sealer protects concrete surfaces from staining, dirt and water damage, and leaves a clear, wet look. It is ideal in high traffic areas, indoors and out.

See manufacturer's instructions online.

How to polish concrete:

Clean the fully cured (minimum 10 days, ideally up to 28 days) concrete to remove any grit that could gouge the concrete as you grind.

Patch any minor flaws or holes with a patching slurry prior to polishing. Mix up the slurry using a combination of cement, fine sand, water, and pigment.

Remove any dags or high points with one of our diamond turbo cup wheels, with water.

Start by polishing with the coarsest pad (#50 or #60 grit), depending on the desired finish.

Go over the entire surface. Use the polisher in a circular motion (in the direction that it spins) from left to right or top to bottom going halfway over the area you have already done.

Hold the polisher as flat as possible on the surface and apply even, light pressure to prevent swirl marks.

Slower speed is usually better than high speed, but you may need to experiment to see what works best with your tools/pads/job/experience.

Use hand pads of same grit to polish areas the polisher can't reach.

See my range here.

Change to a #100 grit pad and polish the entire surface again. Repeat this process, working progressively through all the grits till the desired shine is achieved. The level of gloss is determined by the stage at which you cease polishing in the concrete polishing process. Full high gloss is achieved with #800, #1500 and #3000 pads.

Clean, then let the surface dry.

If applying sealer, follow the manufacturers instructions. Some sealers require the surface to be polished only to #800 grit so that it can bond to the surface, so don't over polish.

Note - When workers cut, crush, drill, polish, saw or grind products that contain silica, particles are created, which are one-hundredth of the size of a grain of sand. These can get stuck deep in the lungs. Ensure precautions to limit exposure to dust are in place.

Use a half face respirator or a PAPR (Powered air purifying respirator).

See the WA government's info on silica dust here.

Disclaimer: the information on this website is provided in good faith and believed to be reliable and accurate at this time. However, the information is provided on the basis that the reader will be solely responsible for assessing the information and its veracity and usefulness. UDT shall in no way be liable, in negligence or howsoever, for any loss sustained or incurred by anyone relying on the information, even if such information is or turns out to be wrong, incomplete, out-of-date or misleading.

EHWA Weha