Diamond Cup Wheels and Grinding Heads

I stock a range of common diamond cup wheels in both 125mm/5" and 175mm/7" in stock.

For a guide on grinding, see at the bottom of the page.

The Mini Cup wheels are designed for grinding in corners or small spaces.

All types are M14 thread, so fit on most angle grinders.

For fast and smooth working performance on hard concrete, with easy grinding on edges or corners.

Available in 50mm and 75mm cup or 70mm segmented.

Medium grit - #30/#40 grit.

Ensure small cup wheel is compatible with your grinder (ie grinder will be what hits wall first).

Spiral diamond grinding wheels are for general grinding with.

Fewer segments grind faster, but more segments suits softer concrete and will give longer life.

Turbo diamond grinding wheels are for aggressive grinding of masonry and concrete.

The 24 segment turbo wheels are less aggressive than the 12 segment wheels, and will last longer, but have a higher initial price. Usually do not leave marks.

Arrow cup wheels have a segment with a sharp leading edge for slicing, grinding and scrapping at the same time. Along with their coarse diamonds, this makes them aggressive, and ideal for glue removal and quick removal of thick layers. Used for general grinding as well as adhesive, epoxy and paint removal.

Rhomboid cup wheels are designed to remove glue, mastic and paint from soft or abrasive concrete.

They have an aggressive segment design, which provides fast grinding.

Although the segment is smaller than normal cup wheels, these cup wheels can provide fast grinding speed and outstanding performance.

More segments means the cup wheel will last longer, but will have a higher initial price.

Double row cup wheels are designed for general purpose grinding, and removal of imperfections and concrete bumps. They may leave marks on the concrete.

The double row gives them a smoother finish and a very long life (expect between 80 and 120 hours of usage depending on application).

Single row cup wheels are more aggressive.

Spiky cup wheel is for grinding on concrete and terrazzo floor, with good performance on hard concrete. It is also for paint, bitumen, carpet and glue residues and thin epoxy removal. These wheels are very smooth to use, cut very well, and leave no swirl marks if used correctly.

See seperate page here.

PCD cup wheels (Poly Crystalline Diamond) - see them here

Note - When workers cut, saw, crush, drill, polish or grind products that contain silica, particles are created, which are one-hundredth of the size of a grain of sand. These can get stuck deep in the lungs. Ensure precautions to limit exposure to dust are in place. See our dust collection accessories here

Use a half face respirator or a PAPR (Powered air purifying respirator).

See the WA government's info on silica dust here.

UDT 50/70/75mm Mini Diamond Cup wheels |

|||||

|

|||||

UDT 4"/100mm Diamond Cup Wheel - Premium |

|||||

|

|

DBS4CUP High quality premium turbo cup wheel for Concrete. Medium Grit 10.0mm segment thickness 22.23mm centre $95 incl GST ea . |

||||

UDT 4"/100mm Diamond Cup Wheel - Premium |

|

|

DBS4CUPCON High quality premium Arrow styled cup wheel for Granite & Concrete (soft bond). Coarse diamond 6.0mm segment thickness M14 Thread suits most small angle grinders $95 incl GST ea (limited stocks) |

UDT 5"/125mm Diamond Cup Wheels - Premium |

|

|

DBS5TURBOSB F, M or C High quality Korean turbo cup diamond grinding wheel with a very soft bond for hard concrete Available in fine, medium and coarse. 7/8" (22.23mm centre) $135 incl GST ea |

7"/175mm TURBO DIAMOND CUP WHEEL |

|

|

24 SEGMENT M14 thread or 22mm centre For concrete DBS7SEG24 $180 ea inc GST |

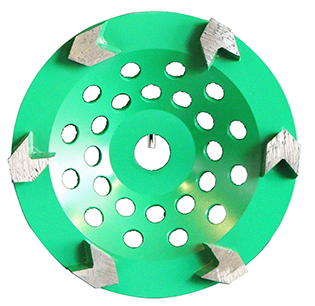

7"/175mm ARROW DIAMOND CUP WHEEL 25/30 GRIT MEDIUM BOND |

|

|

MEDIUM BOND for medium concrete - or - #30 Grit DBS7ARROW6GREEN (medium bond) $150 each inc GST Also available - All 7/8" (22.23mm centre) |

7" ARROW DIAMOND CUP WHEEL 25/30 GRIT SOFT BOND |

|

|

Soft Bond for Hard Concrete (very soft bond to suit Australian hard concrete) #16 Grit DBS7ARROW6B 10mm height - DBS7ARROW6P Premium 6mm height - Also available - 5"/125mm DTA arrow cup wheel $125 incl GST ea All 7/8" (22.23mm centre) |

7" RHOMBOID CUP WHEEL MEDIUM BOND 12 SEGMENTS |

|

|

7" RHOMBOID CUP WHEEL For medium concrete #16 GRIT or #30 GRIT 6 or 12 SEGMENTS DBS7BLUE/16/12SEG or DBS7BLUE/30/12SEG $125 (6 segments) ea inc GST All 7/8" (22.23mm centre) |

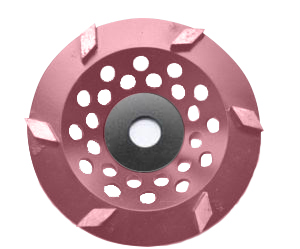

7" RHOMBOID CUP WHEEL SOFT BOND 12 SEGMENTS |

|

|

7" RHOMBOID CUP WHEEL For hard concrete #16 GRIT or #30 GRIT 12 SEGMENTS DBS7PINK/16/12SEG or DBS7PINK/30/12SEG $150 ea inc GST All 7/8" (22.23mm centre) |

7" RHOMBOID CUP WHEEL SOFT BOND 6 SEGMENTS |

|

|

7" RHOMBOID CUP WHEEL For hard concrete #16 GRIT or #30 6 SEGMENTS DBS7PINK/16/6SEG or DBS7PINK/30/6SEG $125 ea inc GST All 7/8" (22.23mm centre) |

7" RHOMBOID CUP WHEEL MEDIUM BOND 6 SEGMENTS |

|

|

7" RHOMBOID CUP WHEEL For medium concrete #16 GRIT or #30 6 SEGMENTS DBS7BLUE/16/6SEG or DBS7BLUE/30/6SEG $125 ea inc GST All 7/8" (22.23mm centre) |

7" RHOMBOID CUP WHEEL HARD BOND - 6 or 12 SEGMENTS |

|

|

7" RHOMBOID CUP WHEEL For soft concrete #16 GRIT or #30GRIT 6 or 12 SEGMENTS DBS7BLACK/16/12SEG or DBS7BLACK/30/6SEG $125 (6 segments) ea inc GST$150 (12 segments) ea inc GST All 7/8" (22.23mm centre) |

Double Row Cup Wheels |

|

|

5"/125mm or 7"/175mm DBS125CUP DBS175CUP DTA 175mm Single Row Cup wheel All 7/8" (22.23mm centre) |

| Tyrolit Adaptor Converts 22.23mm (7/8") bore cup wheels to M14 thread Suits most angle grinders P/N 20035845 $55 ea Incl GST |

|

Prices correct as of 1/9/25 but subject to change.

Please see my Contact page for Australia wide delivery information.

A Guide to Concrete Grinding:

While this introduction is basic only, it does give you a few ideas and considerations when grinding concrete.

Concrete grinding is the process of removing high points, contaminants, and loose material from a concrete surface using a grinding machine. When grinding concrete, the bond of the diamond cup wheels should normally be the opposite of the concrete, ie use a soft bond on hard concrete, and a hard bond on soft concrete.

Use a larger diamond grit (lower number) for faster removal of concrete and for harder concrete.

If you mis-match, the results will be poor. A hard bond with hard concrete will not grind, whereas a soft bond on soft concrete will wear out the cup wheel prematurely.

It is hard to guess the hardness of concrete. I suggest you start with a hard bond (for soft concrete).

If it is not cutting, or is very slow, try a softer bond.

Grinding hard concrete does not produce much dust, and it is usually soft and non abrasive. The diamonds cut, blunt and break as normal, but the metal bond surrounding them is not worn away easily without the dust, so the diamonds are not exposed as much as with soft concrete. The diamond segment glazes over and stops working and rubs on the floor instead of cutting it. You can use larger diamonds (around #20 grit) or a softer bond to increase dust production. Also, reduce the surface area with fewer segments to increase the weight per square centimetre.

Grinding soft concrete usually produces sufficient gritty, abrasive dust that will wear away the bond and expose the diamonds adequately. In fact, too much dust can cause the grinding wheel to wear too fast, so vacuum up excess dust. Reduce the weight on the wheel or increase the surface area with more segments to reduce the weight per square centimetre.

Inspect your grinding discs regularly to make sure diamonds are exposed adequately and that it is not overheating.

Even the best discs will perform badly if used in the wrong application.

4 steps to grinding a concrete floor

- Know the Surface – A diamond grinder is suitable for removing light, thin layers, not aggressive profiling and shaping.

- Prepare the surface – If the floor has some coatings on it (even small patches), these need to be removed before grinding. One run over is not enough, and proper surface rehabilitation must be done over several steps, each step graduating to the next to ensure a smooth finish to the floor.

- Select the correct diamond disc – Each particular floor is going to dictate your choice of diamond disc. There are a number of things to consider which diamond segment is appropriate.

- The bond is the material that initially holds the diamonds in place, but also wears away to expose the diamonds. A hard bond is best when dealing with abrasive material like soft concrete or rain-damaged pavement. Medium bond tends to perform poorly with hard materials, but wears away more quickly on abrasive materials. Soft bonds are ideal on hard materials because it wears away quickly, exposing a layer of diamond to grind the surface.

- Grit is the diamond size in the bond, and ranges from coarse to fine. Start with a coarse grit (#16-25 grit) to remove the uneven areas. Double the grit size with each stage, gradually breaking down the surface irregularities until the surface is sufficiently smooth.

#16 grit is very coarse for removing coatings like glue, lacquer, paint, epoxy etc

#25 grit is for rough grinding such as levelling and floor preparation.

#40/50 grit is for medium grinding applications

#80 - #100 is for fine grinding.

- The shape of the diamond segments used has an impact too. Arrow heads have sharp leading edges for slicing and are effective for glue removal. Square segments have a long leading edge, so are ideal on uneven concrete. Round headed diamonds have a subtle leading edge so are perfect for working with finer grits.

- Number of segments - the more segments reduces pressure, whereas less increases pressure per segment. - Use correct grinder weight – The weight on the machine can affect the wear and tear on the machine, as well as effectiveness of grinding. Heavier pressure is more aggressive on the surface, where as lighter pressure is less aggressive.

Tips:

Dampening the concrete before grinding, or even spraying a little water may assist with your job ( be careful mixing water with electricity - use an RCD). It will make a grinding paste.

Similarly, clean builders sand on the surface, or reducing dust extraction, will help the grinding process.

A grinding compound such as Worx+ Totally Cut Sikk can assist grinding.

Do not let cup wheels get too hot. Over heating will cause the cup wheels to glaze over.

If cup wheels glaze up, adding clean builders sand to the surface can open up the segments again.

For tips on using cub grinders see the bottom of this page.

Remember - every job is different. The enormous combinations of different types of surfaces, different cup wheel styles, with many different bonds and grits, plus different machines and varied operator experience means it is impossible to guess what will give the perfect result the first time. Some experimentation is often necessary to achieve the required results.

Note - If you are cutting dry, always be aware of the danger of breathing in the dust. Ensure a dust extraction system is used with a suitable filter fitted. Use a half face respirator or a PAPR (Powered air purifying respirator). Even if you are cutting wet, the slurry created can dry out and create a hazard for other users - dispose of slurry as per your local regulations.

Disclaimer: the information on this website is provided in good faith and believed to be reliable and accurate at this time. However, the information is provided on the basis that the reader will be solely responsible for assessing the information and its veracity and usefulness. UDT shall in no way be liable, in negligence or howsoever, for any loss sustained or incurred by anyone relying on the information, even if such information is or turns out to be wrong, incomplete, out-of-date or misleading.