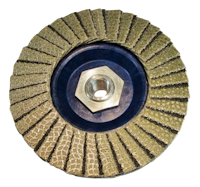

Diamond Flap Wheels

KGS Diamond Flap Wheels are used for shaping, beveling and grinding edges on natural stone, marble, granite, concrete and terrazzo, tiles, alumina ceramic, silicon carbide and engineered stone.

They can be used wet or dry, have a fast cutting speed and high stock removal rate.

A flap disk is easier to use and more forgiving than heavier cup wheels, with no vibration.

All our flap wheel are made in the EU.

KGS DIAMOND is the world's leading manufacturer of flexible diamond abrasives and electrolytically metallised fabrics. Founded in Switzerland in 1952, KGS has sales and distribution offices in Europe, North America, China and Australia as well as four manufacturing sites located in Switzerland, The Netherlands, Hungary and Portugal.

When used on alumina ceramic tiles, these flap wheels will not blacken the tile like grinding wheels.

Note:

A variable speed grinder is recommended for the low speed. It is as efficiently as high speed, and the lower speeds keep the wheels cool. Alternatively, swapping flap wheels regularly also keeps them cool.

Overheated wheels will loose flaps, and in severe cases, can lose many flaps at once.

Tips:

- #50 has a ggressive removal power on hard materials (Grit 50 is officially approved for use on Dekton® )

- #60 has high removal power on almost any material.

- #200 and #400 grit is best for polishing (even on alumina ceramic). Or follow up with MM2A polishing pads.

- The Gold series #60 are best for removing epoxy glue off alumina ceramic tiles.

- Work flat

- Use as little pressure as possible - above #200 grit use machine weight only

- Use quick movements to prevent overheating the resin bond

Our flap wheels are also ideal for sharpening tungsten carbide teeth on machinery such as stump grinders, excavators, trenchers, as well as boring, mining and drilling machines.

Sharpen with the Gold #60 grit, and finish off with the #120 grit.

Our Range:

The KGS Gold series are a flap disc with extreme grinding and an incredible life time, and very suitable for a straight stone edge. They deliver a smooth consistent finish with no chipping.

These flap discs, made from 100% diamond flaps, are the value-for-money option compared to cup wheels.

The KGS Silver series are a Hybrid T Flap Discs, which uses polishing and grinding pads, so is ideal for grinding and polishing engineered stone. They are an ideal choice for concrete polishers doing edge work, or edging of glass.

They feature fast cutting speed, exceptional lifetime, are very easy to use and comfortable action with no vibration.

They produce a smooth even finish with no chipping.

The KGS Shark Range is an ideal replacement for coarse grinding and shaping using a cup wheel.

They are economically priced and are made from a combination of diamond flaps discs and conventional abrasive flaps.

They are an ideal choice for concrete polishers doing edge work on concrete and terrazzo.

Fast cutting speed, exceptional lifetime, very easy to use, with a comfortable action with no vibration.

They give a smooth, even finish with no chipping.

Includes M14 adaptor (these are optional on Gold and Silver series)

Note - If you are grinding dry, always be aware of the danger of breathing in the dust.

Ensure a dust extraction system is used with a suitable filter fitted. Use a half face respirator or a PAPR (Powered air purifying respirator). Even if you are grinding wet, the slurry created can dry out and create a hazard for other users - dispose of slurry as per your local regulations.

KGS Gold Line Hybrid Flap wheels |

||

|

4.5"/115mm |

|

KGS Silver Line Hybrid T Flap Discs |

||

|

4.5"/115mm |

|

KGS Shark Flap Wheels

|

4.5"/115mm |

|

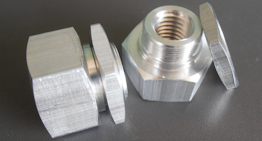

Optional M14 adaptor:

M14 female to 22.23mm (7/8" )

Supplied with Shark flap wheels, but also available as an option.

For use on KGS flap wheels only (not cup wheels)

$20 each incl GST

See the KGS Gold series Flap wheels in action in the KGS video here:

Prices correct as of 1/9/25 but subject to change.

Please see my Contact page for Australia wide delivery information.